Recently, Huade Hydrogen Energy delivered a 70KW fuel cell stationary power generation system to a customer in India, helping the customer build a hydrogen-electricity coupling demonstration project for the Indian government.

The CARNEU-70 fuel cell power generation equipment provided by the company to India this time is a product customized and developed for the hydrogen-electricity coupling comprehensive energy project.

(1) Adopt ultra-low air supply pressure design

In order to reduce the hydrogen in the front-end hydrogen storage dead zone, increase the release volume of the hydrogen storage system, and reduce the hydrogen storage volume and cost. The system adopts a low-pressure air supply scheme. The front-end air supply pressure of the fuel cell system is 2 BAR, and the internal working pressure of the stack is 0.2 BAR, supporting the system's net output of 70KW. Through improvements to the air intake system and stack, the hydrogen release ratio of the hydrogen storage module at the front end of the fuel cell can reach 99%.

(2) Adopt a multi-stack series-parallel solution and support single-stack plug-in replacement

The core of the system stack adopts the company's independently developed single-stack 15KW module, consisting of multiple stacks connected in series and parallel. When one or more stacks in the stack module fail, the failed stack can be simply pulled out for inspection and repair. The remaining system can still operate at reduced load to ensure uninterrupted power supply; on the other hand, it can also be directly replaced. And inserting a new battery stack ensures the system operates at full power at the fastest speed, effectively ensuring users' power needs.

(3) Use fixed power generation stacks

Based on the working characteristics of the stationary fuel cell power generation system, the stack has been optimized and improved. The proton exchange membrane thickness, catalyst loading capacity and bipolar plate thickness have all been significantly improved compared to automotive stacks. In view of the characteristics of power generation scenarios that require long-term operation at high voltage, the working characteristics of membrane electrode catalysts under high pressure are improved, the hydrophilic properties of carbon paper are improved, and the airtightness of bipolar plates under long-term operation is also improved. properties and conductivity, effectively improving the durability of the stack and achieving an effective balance between performance and cost.

(4) Adopt explosion-proof design

The fuel cell system is divided into explosion-proof zones and is divided into hydrogen-related areas and non-hydrogen-related areas. Hydrogen-related areas use explosion-proof electrical components, and non-hydrogen-related areas adopt positive pressure explosion-proof designs. The system is designed with various protections such as hydrogen leak alarm, smoke alarm, over-temperature alarm, and video monitoring. Supports remote monitoring, remote start and stop, power adjustment and other functions.

(5) Adopt intelligent energy management system

Using the company's independently developed intelligent energy management system, it can intelligently control the SOC power of the battery module according to power demand, supporting up to 100KW system power output. The system also supports two working modes: "electrically controlled heat" and "thermal controlled electricity" for users to choose according to actual needs. When the fuel cell system is working, the system's hydrogen consumption, net output power, single cell voltage and other operating parameters can be monitored in real time.

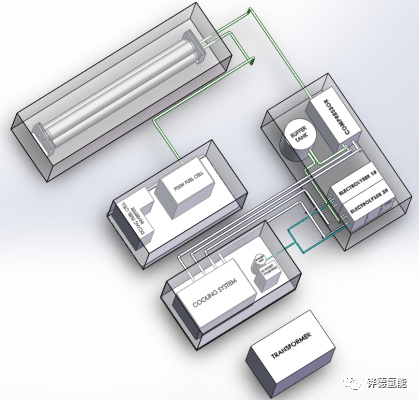

Figure 4 Physical appearance of the product

In addition to the delivery of the 70KW fuel cell system, the company also provided customers with the design and consultation of a complete hydrogen-electric coupling technology solution for hydrogen production, hydrogen storage and power generation, playing an important role in the customer's final bid.

Figure 5 Overall planning and design of hydrogen-electricity coupling project

Under the global wave of hydrogen energy, hydrogen energy technology has gradually attracted the attention of the Indian government. Therefore, the two parties also signed a strategic cooperation agreement for further in-depth cooperation to develop the Indian market.