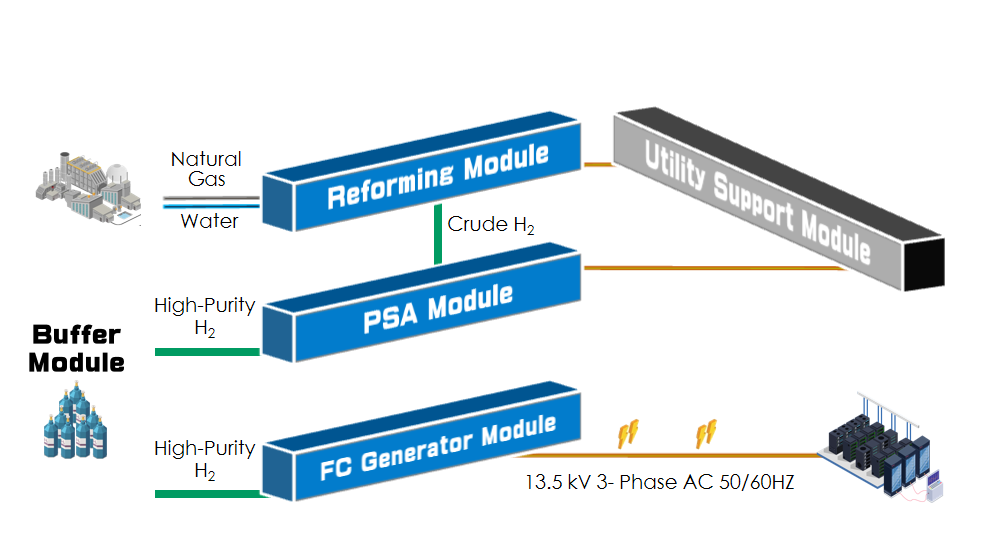

This 1.5MW natural gas reforming fuel cell data center power system includes core modules: reforming hydrogen production, PSA, utility support, buffering, and fuel cell power generation. The hydrogen production module delivers 1000 Nm³/h hydrogen, the fuel cell module provides stable, efficient 1.5MW capacity.

Primary Power Application

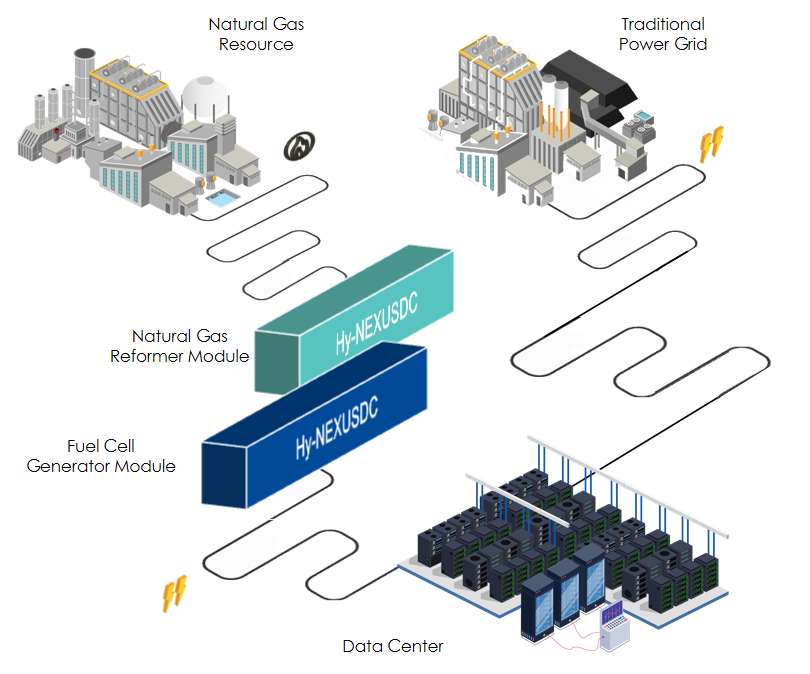

While primary power setups remain popular, more clients now seek enhanced flexibility and control via microgrids. For customers opting for any Hy-NEXUSDC microgrid application, supplementary on-site equipment is provided. During primary power use, if the grid fails, it switches to standby till grid power resumes, or operates alongside backup diesel generators to lower diesel usage.

Backup Power/Off-grid Application

Hy-NEXUSDC’s off-grid solution uses load-following—adjusting power output to match site demand. It lets clients operate grid-independently now, with future grid-connection readiness. When grid’s available, reconfigure to primary power, microgrid or advanced microgrid setups.

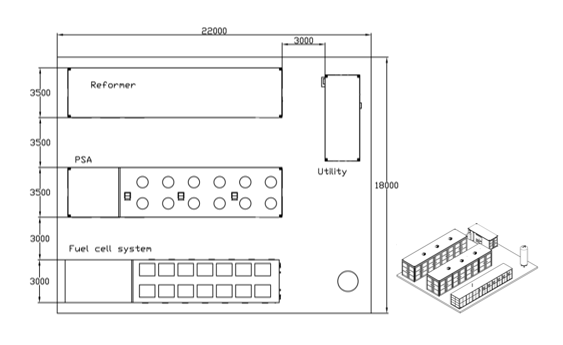

General Layout

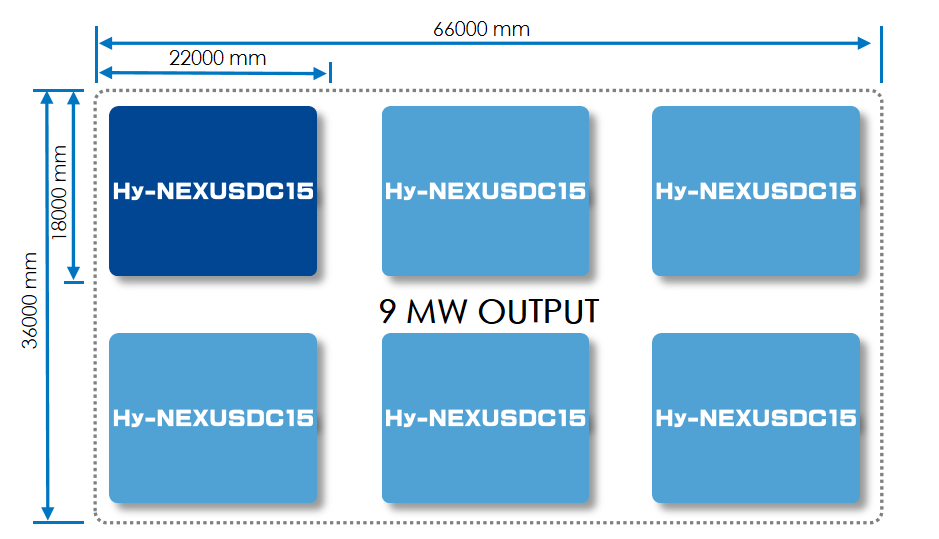

Modular Expansion Layout

The Hy-NEXUSDC Natural Gas - Hydrogen Fueled Energy Solutions leverages a modular design centered on its 1.5 MW base block—an industry-proven building block that enables seamless scaling to 9 MW or higher. Its compact, space-saving footprint is optimized for data centers, fitting effortlessly into constrained environments (e.g., edge facilities or urban colocation sites) while supporting large-scale enterprise deployments. Modular expansion eliminates upfront overbuild: data centers start with 1.5 MW and grow to 9 MW or more as demand increases, ensuring cost-effectiveness and future-proofing. This design not only maximizes real estate efficiency but also delivers consistent, quiet, and efficient power—critical for meeting the reliability and uptime needs of modern data center operations, from small edge nodes to high-capacity hyperscale campuses.

Product Parameter

|

Technical Type |

|

|

Hydrogen Production from Natural Gas |

Natural gas steam reforming + PAS |

|

Fuel Cell Power Generation |

PEM |

|

Output |

|

|

Net Power Output (AC) |

1.5 MW |

|

Electrical Connection |

13.5 kW, 3-phase, 50/60 HZ |

|

Input |

|

|

Natural Gas |

425 Nm3/h |

|

Water |

0.68 t/h |

|

Physical Dimensions |

|

|

System Floor Area |

22m*18m |

|

Reforming Module Dimensions |

15m*3.5m*3.8m |

|

PSA Module Dimensions |

15m*3.5m*3.8m |

|

Utility Support Module Dimensions |

6m*2.43m*2.59m |

|

FC Generator Module Dimensions |

15 m*3 m*2.59 m |

|

Operating Conditions |

|

|

Ambient Temperature |

-25℃ ~ 45℃ |

|

Ambient Humidity |

0% ~ 100% |

|

Installation Method |

Outdoor |

|

Running Time |

≥8400h (per year) |

|

Reforming Module Parameters |

|

|

Hydrogen Output |

1000 Nm3/h |

|

Hydrogen Outlet Pressure |

1.5 MPa G |

|

Hydrogen Production Rate |

2.35 |

|

Natural Gas Inlet Pressure |

2.5 MPa |

|

FC Generator Module Parameters |

|

|

Fuel Cell Type |

PEM |

|

Rated System Output |

1.5 MW |

|

Rated Voltage |

13.5 kV 3-Phase 50/60 HZ |

|

Number of Fuel Cell Modules |

14 |

|

Rated Output Power of Single Module |

107.2 kW |

|

Fuel Cell Power Generation Efficiency |

50 % |

|

Hydrogen Consumption |

1000 Nm3/h |