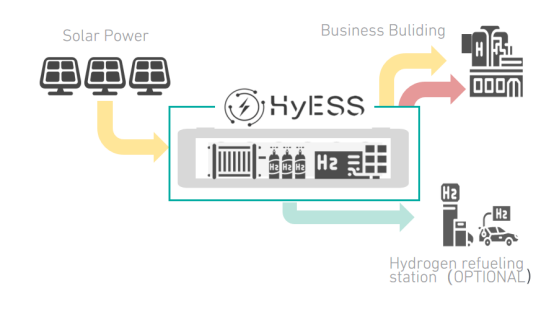

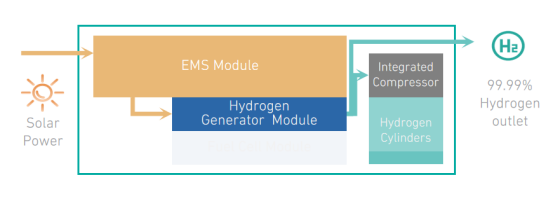

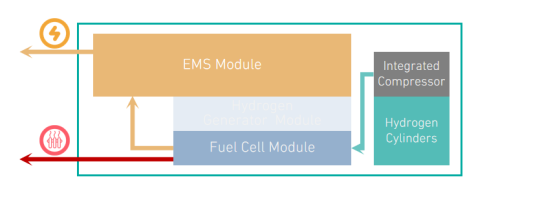

Integrated EMS

The system integrates hydrogen production, charging and fuel cell cogeneration control. It not only improves the cooperation between the system modules, but also simplifies the system control structure and reduces the cost. In addition, the control system also supports remote monitoring, remote start and stop and power regulation.

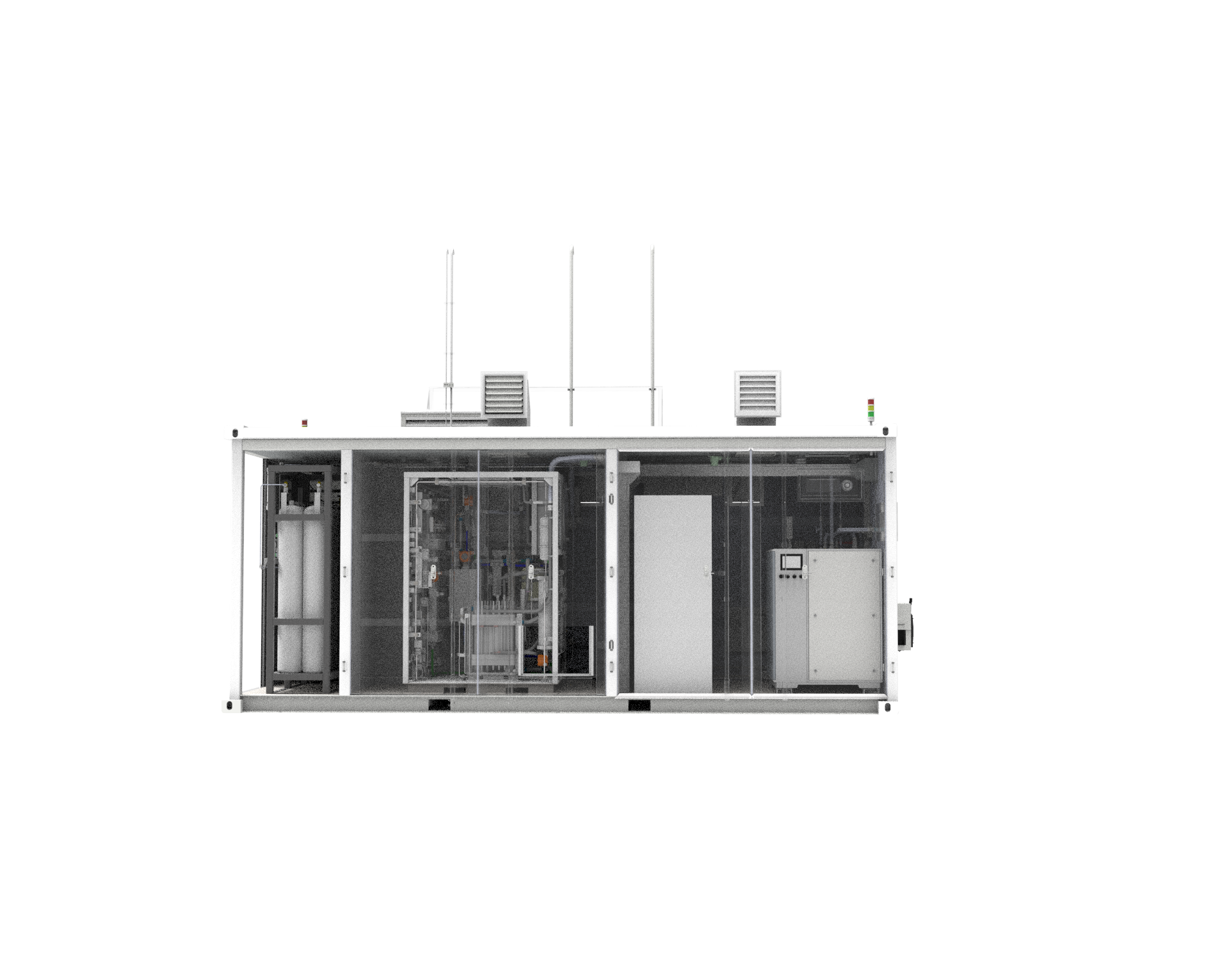

Highly integrated modular design

The system is divided into three parts: hydrogen production bin, hydrogen storage bin and fuel cell & EMS bin.

High level of explosion-proof design

The system adopts explosion-proof safety design, which is divided into hydrogen-related areas and non-hydrogen-related areas. Explosion-proof electrical components are used in hydrogen-related areas, and positive pressure explosion-proof design is adopted in non-hydrogen-related areas. Hydrogen leakage alarm, smoke alarm, overtemperature alarm, video monitoring and other protection are designed in the system.

Cold start design

The system designed a cold start unit, which can achieve -20℃ fast start. This improves the adaptability of the product to be used in cold areas such as the north.

Hydrogen generating condition

Fuel cell operation condition

|

Module |

Item |

Parameters |

|

Electrolyzer(PEM) |

Rated Hydrogen Production |

5-50Nm3/h |

|

|

Pressure |

0-3MPa |

|

|

Rated DC Consumption |

<5kWh/Nm3 H2 |

|

Fuel cell module |

Rated Electrical Power |

50kW-1MW |

|

|

Rated Thermal Power |

40kW - 900kW |

|

|

Output Hot-water Temperature |

60℃~ max.65℃ |

|

Hydrogen storage |

Hydrogen Storage Capacity |

Custom Designed |

|

|

Hydrogen Storage Type |

20 MPa Cylinder / Hydrogen Tank/ Hydrogen Vessel |

|

Electrical

|

Power quality |

380VAC, 3P |

|

|

Frequency |

50Hz |

|

|

Connecting |

off/ on Grid Connection Optional |